Brand partnership • Semiconductor Industry Subject Matter Expert | Story Teller | Speaker & Educator | Join Us To Acquire Knowledge Of Industry Roadmaps, Build Business Partnerships, And Network With Industry Leaders.

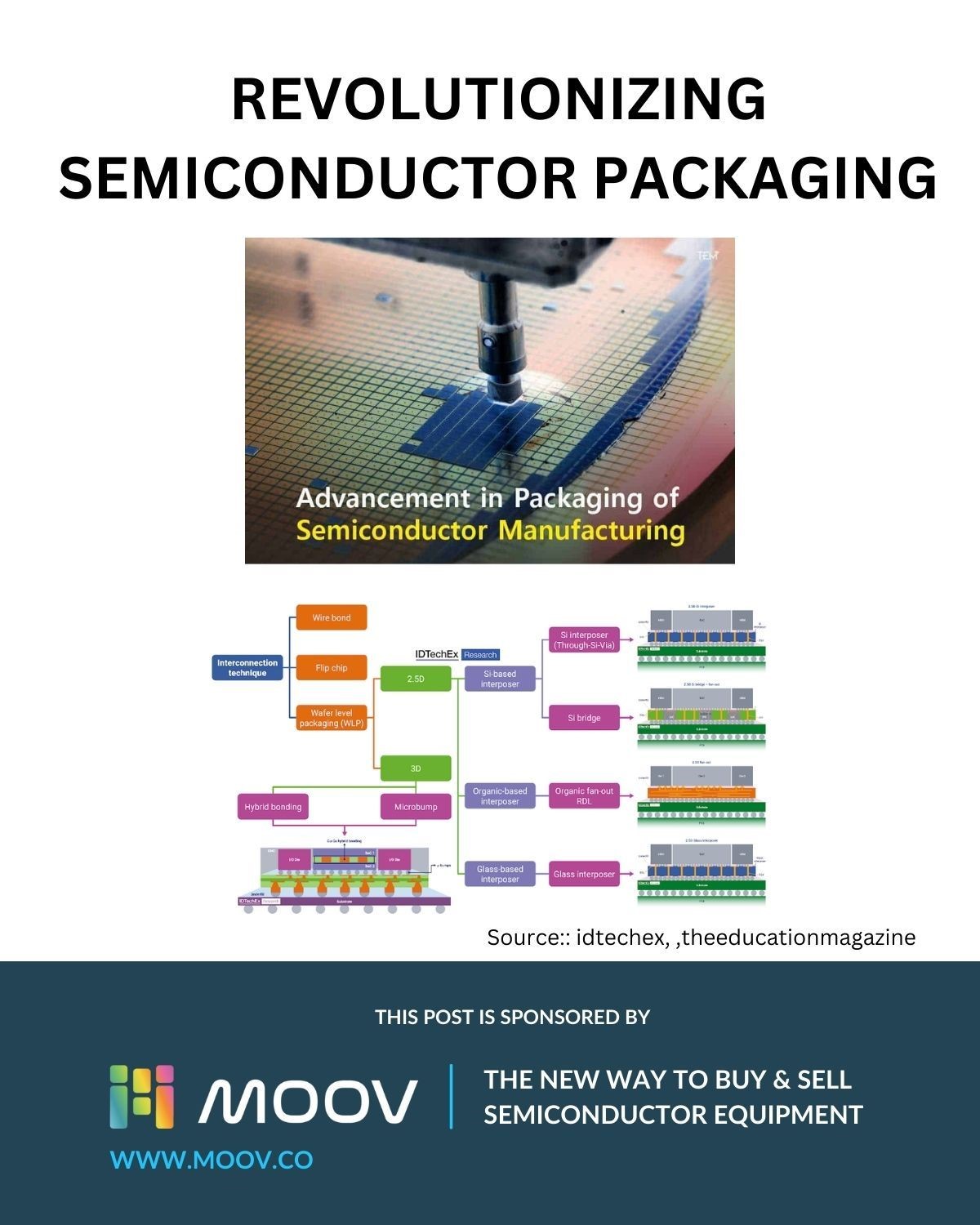

ADVANCED SEMICONDUCTOR PACKAGING TECHNOLOGY TRENDS: 2.5D & 3D INSIGHTS 1. Semiconductor packaging has advanced from basic 1D PCB to 3D hybrid bonding, enabling ultra-fine interconnect pitches and bandwidths exceeding 1000 GB/s with high efficiency. 2. This field focuses on optimizing four key areas: enhancing power efficiency, increasing bandwidth and I/O points through reduced pitch, adjusting packaging size for different computing needs, and reducing costs with alternative materials and improved manufacturing. 3. The 2.5D and 3D packaging techniques offer diverse choices like Si, Organic, and Glass-based interposers, each with unique benefits and challenges, alongside advancements like microbump and hybrid bonding technologies. The evolution of semiconductor packaging has progressed from basic 1D PCB designs to advanced 3D hybrid bonding at the wafer level, enabling single-digit micronmeter interconnect pitches and over 1000 GB/s bandwidth with enhanced energy efficiency. This advancement hinges on four pillars: improved power efficiency, enhanced performance through increased bandwidth and reduced interconnection pitch, adapting area requirements for high-performance computing and 3D integration, and cost reduction via alternative materials and manufacturing efficiencies. Diverse techniques define 2.5D and 3D packaging technologies. 2.5D packaging employs Si-based, Organic-based, and Glass-based interposers. 3D packaging sees advancements in microbump technology and the adoption of hybrid bonding, directly connecting Cu-Cu for smaller pitches. Each method offers unique benefits and challenges. Si interposers in 2.5D packaging provide fine routing but face cost and area constraints. Organic materials offer cost benefits but lag in interconnect feature reduction. Glass interposers, emerging in the industry, promise but are currently limited by production capabilities. In 3D packaging, microbump technology contends with scaling challenges, while hybrid bonding excels in bandwidth and power efficiency but faces higher costs and manufacturing complexities. IDTechEx’s report and an upcoming webinar by Dr. Yu-Han Chang delve into these technologies, offering insights into current trends, future developments, market outlooks, and comprehensive industry analysis. Thanks again to IDTechEx for the article. Are you looking to buy or sell used semiconductor equipment? VISIT Moov Technologies Inc. and browse their 4 billion dollars of equipment listings around the world. stay updated with industry shifts, check out the link in the comments. #semiconductorindustry #technology #computerchips